Every project starts with a challenge: a part that wears out too quickly, a sealing issue that halts production, or a component that doesn’t yet exist. At URM we transform those challenges into durable, high-performing rubber parts.

Every custom rubber part starts with a need, sometimes urgent, sometimes complex. You might be replacing a worn component, improving a design, or developing something completely new. Whatever the case, URM translates that need into a clear, workable plan.

What sets us apart is not just our flexibility but also our discipline. Each stage — from defining requirements and selecting materials to prototyping, testing, and production — is carried out under ISO-certified processes. This ensures full traceability, documented quality control, and compliance with the standards our clients expect.

At URM, we don’t just sell rubber products — we create them. Every hose, gasket, or profile that leaves our factory starts life as a raw concept and ends as a precision-engineered component built to perform.

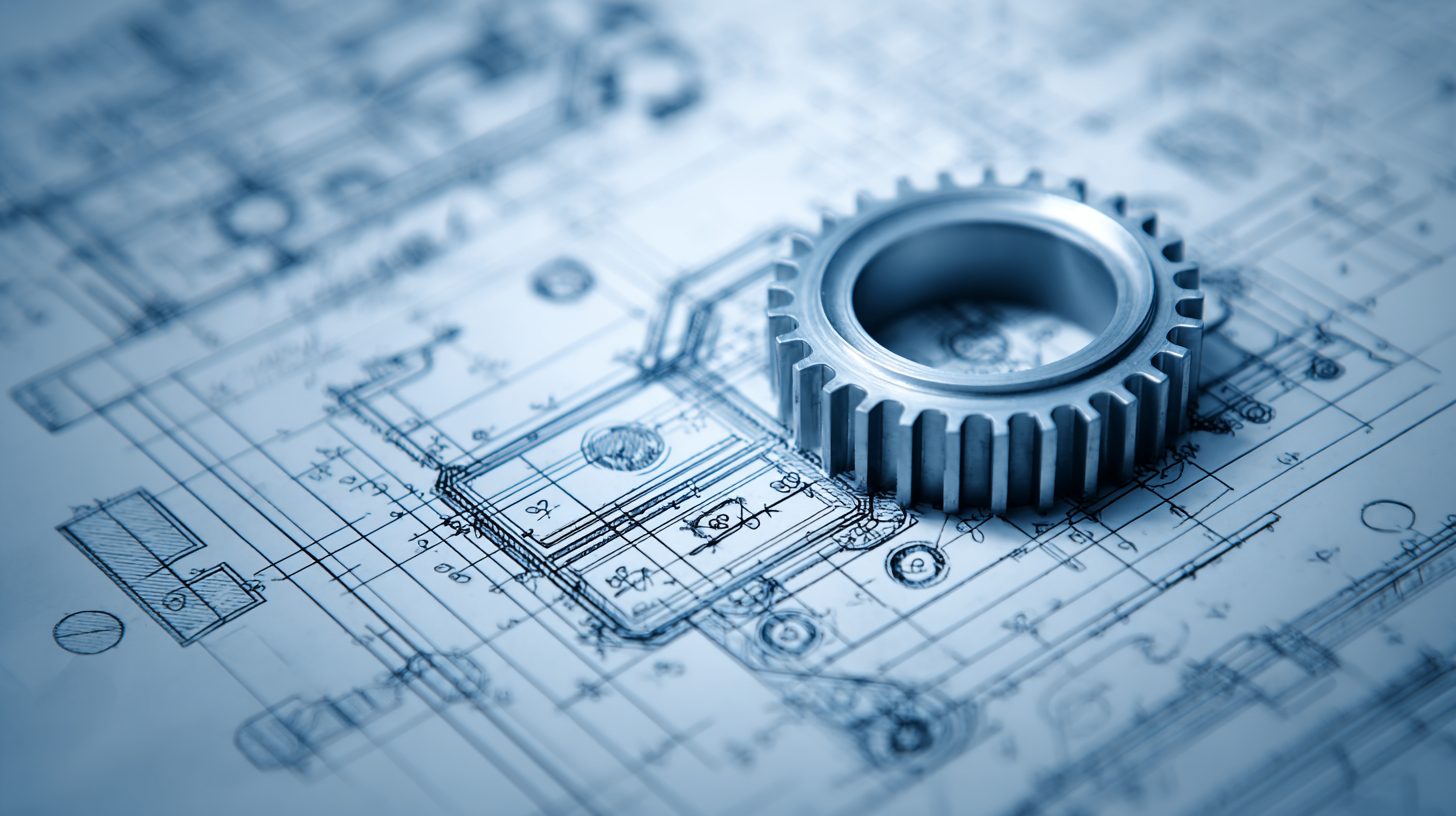

Collaboration from the start

Our process begins with you. Whether you bring us a sketch, a CAD model, or just an idea, our engineers and product designers work alongside your team to define exact requirements. Together, we choose the optimal rubber compound, shape, and production method for your application.

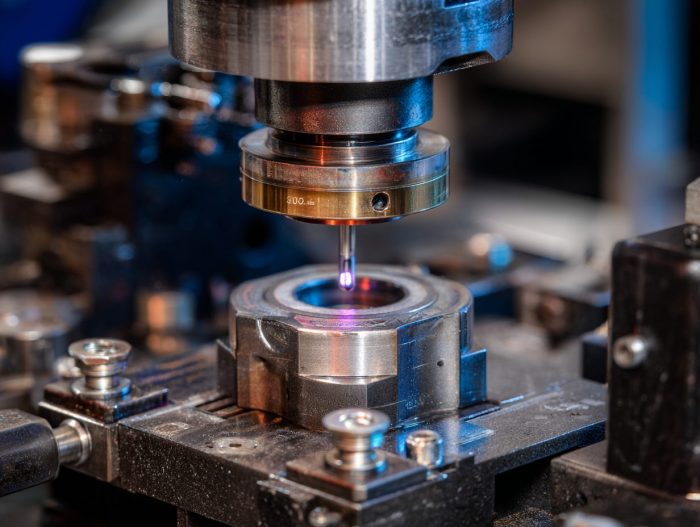

In-house production

We are not resellers. Every part is produced in our own facilities, using advanced molding and extrusion technology. This gives us full control over quality at every stage — from mixing compounds to final inspection.

Quality you can trust

Our manufacturing follows strict quality protocols. Each batch undergoes dimensional checks, hardness and tensile tests, and visual inspections to ensure consistency and durability.

Ongoing support

Our commitment doesn’t end when your order ships. We provide follow-up assistance to fine-tune components in real-world conditions, address any challenges, and optimise performance over time.

What does the part need to achieve? Where will it operate? What failures do we need to avoid? All requirements are documented and translated into technical criteria in line with ISO quality management procedures, so nothing is left to chance.

Before production begins, all raw materials are verified for compliance and traceability. Each batch is tested for hardness, elasticity, and resistance to temperature or chemicals, guaranteeing that only qualified compounds enter the process.

Every step, from mold setup to curing time, is defined in detail. Our ISO procedures require documented parameters for pressure, temperature, and cycle time, allowing repeatable quality and minimal deviation between batches.

During production, sensors and operators continuously monitor critical variables. Deviations are identified and corrected immediately, ensuring that each part meets specifications without rework or waste.

Dimensional checks, visual control, and surface testing confirm that each component meets all requirements. Automated inspection systems work alongside trained specialists to validate both precision and appearance before approval.

Every project provides data for analysis. Feedback from customers, audits, and internal reviews drives our improvement plans. ISO certification keeps this cycle active so that every new order benefits from what we learned before.